Merek:

CBFIBarang NO.:

BBI1000Pelabuhan Pengiriman:

Guangzhou PortJaminan:

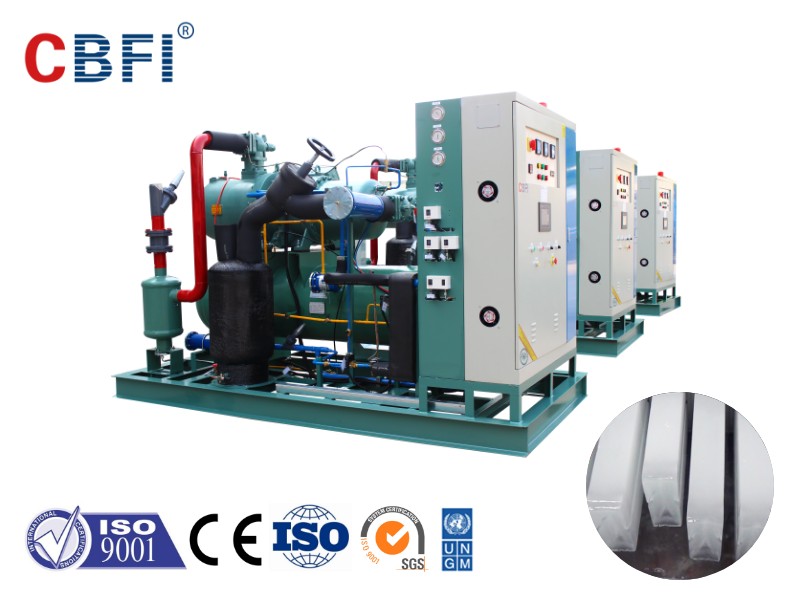

1 yearCBFI BBI1000 100 ton per 24j blok mesin es

fitur CBFI balok es Mesin:

1. hemat daya dan energi hemat. dipatenkan evaporator desain meningkatkan efisiensi pembuatan es dan mengurangi konsumsi energi.

2. Kolam air asin sangat tahan terhadap korosi. Permukaan kolam air asin mengadopsi anti korosi teknologi, dua primer dan satu lapisan atas, permukaan cat tahan terhadap suhu rendah, perendaman air garam jangka panjang tidak jatuh, dan umur layanan lebih dari 35% lebih tinggi dari serupa produk.

3. cetakan es yang disesuaikan dengan ukuran apapun. Cetakan es dapat disesuaikan dengan kebutuhan pasar lokal.

4. tahan lama evaporator. Sangat tebal dinding tabung koil, hingga 3mm tebal, dan umur layanan hingga 20 tahun.

5. kapasitas besar reservoir. dapat memastikan bahwa mesin es dioperasikan di lingkungan dengan perbedaan suhu yang besar tanpa cairan kejutan. itu adalah produk terbaik untuk perlindungan kompresor di antara serupa produk.

detail mesin

|  |

parameter

BBI1000 blok parameter mesin es nama satuan parameter Bitzer parameter kompresor model 4TES-9 pendinginan Kapasitas (kW) 15.92 Daya (kW) 6.62 kondensator model WN-10 panas Pertukaran e (kW) 35.8 suhu kondensasi derajat Celcius (℃) 38 suhu penguapan derajat Celcius (℃) -18 suhu lingkungan derajat Celcius (℃) 32 suhu air derajat Celcius (℃) 20 pendingin R507 tegangan V / P / HZ 380 / 3 / 50 agitator Daya (kW) 2.2 menara pendingin model LX-15 Daya (kW) 0.25 pompa pendingin model GD50-17 kekuasaan 1.5 SS304 dimensi cetakan es L * W * H (mm) disesuaikan dimensi mesin L * W * H (mm) disesuaikan Catatan crane tidak termasuk.

pembuatan balok es

|  |  |

|  |  |

kontrol kualitas

|  |

|  |