Merek:

CBFI1, Aplikasi Produk:

1). Produk akuatik: udang mentah, udang, daging ikan, kerang, dll.;

2). Daging: daging unggas, daging potong, dll.;

3). Mie: pangsit, bakpao kukus, bola ketan, lumpia, dll.;

4). Makanan pengkondisi: produk yang diasinkan, hidangan siap saji, dll.

2. Deskripsi Produk:

Bentuk terowongan freezer adalah terowongan persegi panjang, di mana udara dingin bersirkulasi dan makanan dengan cepat membeku saat melewati terowongan. Perangkat ini memiliki struktur sederhana, kecepatan pembekuan cepat, dapat mewujudkan produksi berkelanjutan, dan cocok untuk pemrosesan jalur perakitan. Makanan dapat dibekukan dalam waktu 60 menit, dan suhu tengah dapat mencapai di bawah -18°C. Suhu masuk atau suhu keluar: +15°C/-18°C. Peralatan dirancang dan diproduksi sesuai dengan persyaratan HACCP untuk memastikan kebersihan dan keamanan makanan.

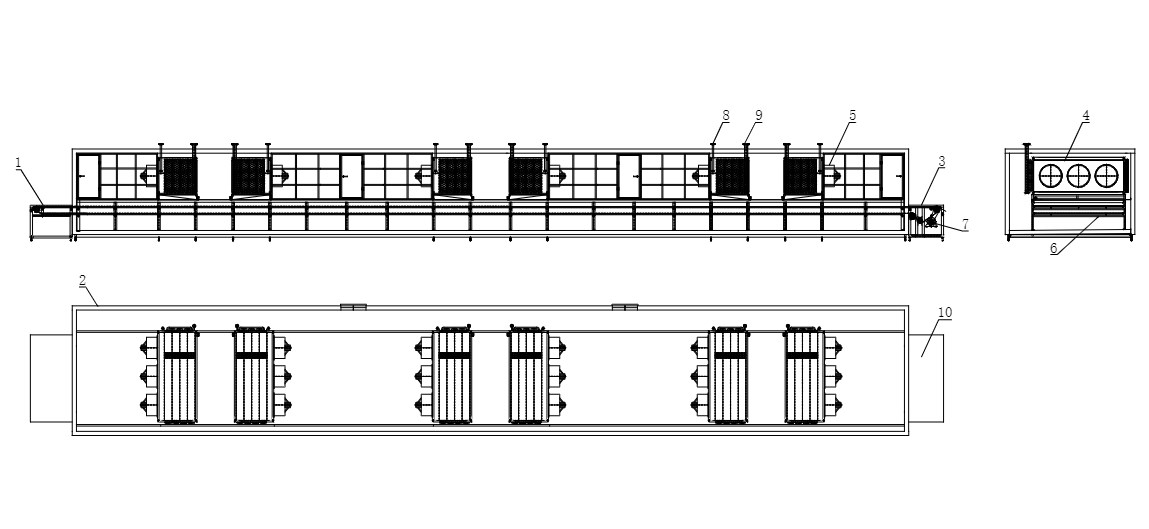

1. Rak makan 2. Badan penyimpanan isolasi 3. Outlet 4. Evaporator

5. Kipas sirkulasi 6. Rangka pijakan baja tahan karat 7. Motor transmisi 8. Pipa suplai cairan

9. Air return pipe 10. Mesh belt/plate belt

3、Product Categories

According to the different conveyor belts, it can be divided into mesh belt tunnel quick freezer and plate belt tunnel quick freezer.

Mesh Belt Tunnel Quick Freezer

The mesh belt tunnel quick freezer is suitable for quick-freezing processing of seafood, poultry meat, vegetables, fruits, pasta, dairy products and other foods. The freezing amount can be 100Kg/h--2000Kg/h.

Structural features:

a 、Simple structure, convenient operation and long service life.

b 、The conveying mesh belt is made of high-strength SUS304 stainless steel mesh, which is safer to use, and the frozen products will not leave traces directly on the surface of the mesh belt. Mesh belt width can be selected upon request.

c 、According to the production requirements, the combination of single and double mesh belts can be selected.

d 、The thermal insulation storage body is made of double-sided SUS304 stainless steel polyurethane storage board, with inspection doors, double-layer sealing devices and heating devices to prevent freezing.

e 、The air guide device in the warehouse adopts high-efficiency and low-noise axial flow fan and thermal fluctuation technology, and the freezing efficiencyis increased by about 15%-30%.

f 、Use water to wash the cream to ensure cleanliness. The evaporator is made of aluminum alloy material, aluminum tube and aluminum fins, which is easy to clean. The design of variable blade distance can effectively prevent frost blocking and prolong the timeof frost flushing. The unique liquid supply method makes the heat exchange more sufficient and the effect more obvious.

g、 The imported frequency converter realizes inorganic speed regulation, and the freezing time can be adjusted continuouslyaccording to the needs, which can adapt to various freezing processes.

h、 Stainless steel electric control box, stable quality, safe and reliable, easy to operate. The control system is equipped with a special alarmdevice andan emergency button to ensure the safe operation of the equipment.

Plate Belt Tunnel Quick Freezer

The plate-type tunnel quick-freezing machine is suitable for quick-freezing processing of high-moisture, soft, and liquid foods, such as fresh meat, fish fillets, shrimp, scallops, pasta and other foods. The freezing amount can be 100Kg/h-2000Kg/h.

Structural features:

a、 Simple structure, convenient operation and long service life.

b、The storage body is made of rigid polyurethane foam, which has good thermal insulation performance. All internal parts are made of SUS304. high-quality stainless steel, which is easy to clean and meets HACCP requirements.

c、Imported stainless steel strips are used, with high toughness and smooth surface.

d、The ice scraping device of the feeding belt can reduce the damage to the steel belt caused by ice and foreign objects.

e、According to the production requirements, single and double strip combinations can be selected.

f、Use water to flush the cream to ensure cleanliness

g、The imported frequency converter realizes inorganic speed regulation, and the freezing time can be adjusted continuously according to the needs, which can adapt to various freezing processing

4、Product Performance Characteristics

1). The "heat fluctuation" blowing method is adopted, and the freezing speed is fast;

2). Rapid freezing at -35°C;

3). It is made of 304 stainless steel spring wire, and the surface is flat; the imported frequency converter is used to realize stepless speed regulation;

4). The cooling fan adopts variable blade pitch, and the frosting interval is long to ensure the continuity of production;

5). The warehouse body is made of polyurethane foam, double-sided 304 stainless steel, good heat preservation effect, hygienic and easy to clean.

5、Product Advantages

1). Continuous and uninterrupted production, reducing manual operation The quick-freezing tunnel can realize continuous quick-freezing work and improve production efficiency. However, the goods entering and exiting the traditional quick-freezing warehouse can only be realized manually. Manually put the food into the quick freezer, start the refrigeration equipment, and quickly cool and freeze the food. When the food freezes, the refrigeration unit turns off. Manually move the goods out of low-temperature cold storage or other places. The use of quick-freezing tunnels can save manual handling procedures. The goods are transported to the tunnel by the conveyor belt. After the goods pass through the tunnel, they are quickly frozen and then shipped out for the next step.

2). Quickly freeze food to maintain the original nutritional value of the food to the greatest extent. The food with color and aroma will quickly pass through the maximum ice crystal formation zone within 30 minutes, so that the core temperature of the food will drop from -1°C to -5°C , The diameter of the formed ice crystals is less than 100μm, which prevents the ice crystals from falling off and piercing the cell wall, reduces the outflow of juice, and quickly freezes food. It is characterized by maintaining the original nutritional value and color, aroma and taste of food to the maximum extent.

6、Company Profile

Guangzhou IceSource Refrigeration Equipment Co., LTD is founded in January of 2004,which is established on the management and manufacture basic of Guangzhou Vista M&E Equipment Co., Limited.

Our factory was located in Panyu District of Guangzhou, Guangdong Province, it is near two famous port of South China Huangpu Port and Nansha Port, and not far from Baiyun airport. It is convenient for load and transport goods and for customers come to visit our factory. Our company is specialize in research, design, produce and sell large production ice cube machine, ice block machine, ice plate machine, ice tube machine and shaved ice machine, and its accessory equipment, for example cold room, crane, ice crushing machine and so on. Machine's output design can start from single small ice machine for produce 1ton ice per day to large scale completely ice making system for produce 50tons ice per day. All components from choosing raw material to processing and finished products, all pass strict inspection, strict quality control, ensure completely ice system with excellent quality. The products are widely applied to different fields, such as food industry, large chain supermarket, retail, aquatic product, chemical industry, water conservancy, power plant, health care, large public project, mine cooling, chemical industry, etc. Independent research and design is the source of technology to update, our company has owned two patented technologies: flat-plate heat exchange and circulating heat gas for ice dropping. These two patents have greatly improved the stability and safety of our ice making machine and ensure machine prominently energy saving, its energy saving rate is more than 30%.It start new generation of energy saving product. Icesource products have passed ISO9001, ISO14001 and CE certificate. We have been keep tracking service condition of our products, have record for more than 400customers in more than 30countries from Africa, Middle East, Southeast Asia, Australia and South America. It bring us rich experience and and valuable data to improve our products for different environment condition. Icesource take "painstakingly created high quality products and wholehearted service" as company tenet, keep developing and perfecting our sales system and after-sale service system, Combined with own advantages, continuous learning foreign mature sales experience and cater to domestic and international market trends and demands. Company adhere to the principle of equal emphasis on social and economic benefits. We will try our best offer customer timely and comprehensive service and support. Icesource adhere people oriented, technology first corporate ideas, view customer's practical needs, improving people life quality and environment for human being existing as a duty. Gathering strong technology, professional talent, and advanced facilities, continuously improve making ice technology, to be leader of ice machine industry.